Hydraulic Reversible Plough Cylinder Manufacturer

Details

Hydraulic Reversible Plough Cylinder Manufacturer

Company Profile

|

Establish Year |

1973 |

|

Factories |

3 factories |

|

Staff |

500 employees including 60 engineers,30 QC staff |

|

Production Line |

13 lines |

|

Yearly Production Capability |

Hydraulic Cylinders 450,000 sets; |

|

Sales Amount |

USD45 Million |

|

Main Export Countries |

America,Sweden,Russian,Australia |

|

Quality System |

ISO9001,TS16949 |

|

Patents |

89 patents |

|

Guarantee |

13 months |

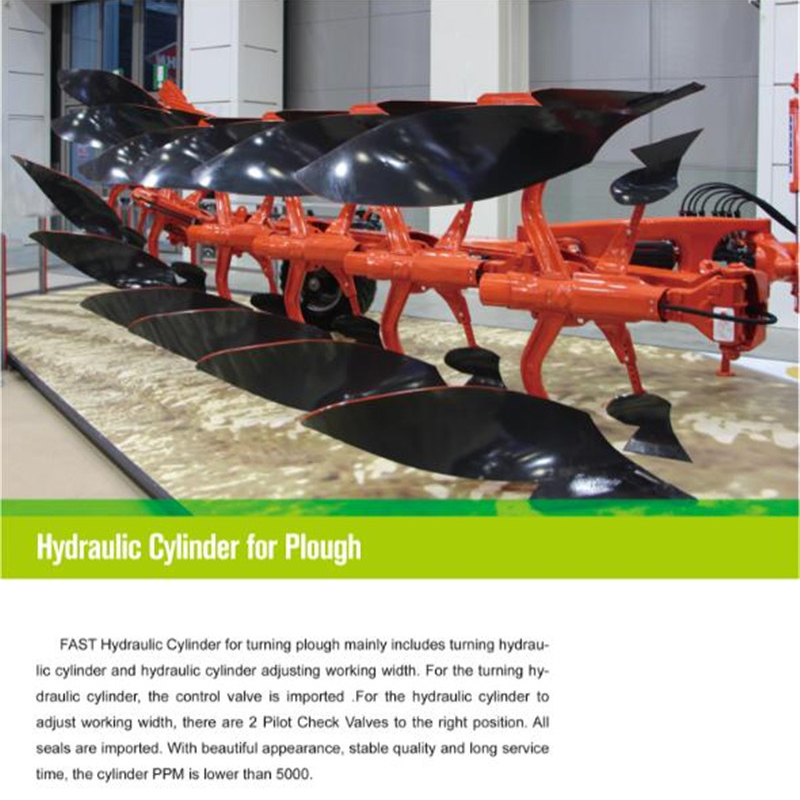

We are manufacture and exporter of Reversible Plough Hydraulic Cylinder used in for agricultural purpose.

The turnover of the reversible plough is done by a Hydraulic cylinder; which reduces the fatigue to tractor driver considerably. Due to smooth turnover, no impact vibrations are experienced. Hence long life to plough & tractors is achieved.

Pushpak Hydraulic reversible plough has two mold board ploughs, mounted back-to-back, one turning to the right, the other to the left. While one is working the land, the other is carried upside-down in the air. At the end of each row, the paired ploughs are turned over, so the other can be used. This returns along the next furrow, again working the field in a consistent direction

The Pushpak Hydraulic reversible Plough is used to turn over the upper layer of the soil, bringing fresh nutrients to the surface, while burying weeds, the remains of previous crops, and both crop and weed seeds, allowing them to break down.

Pushpak Hydraulic reversible Ploughs are available in two / three & four; furrow working configurations, suitable for tractors with various horse powers from 45Hp to 90Hp. The working points are available in Shear type & bar point.

The construction of the Pushpak Hydraulic reversible plough is very strong & reliable with the use of “Box Section Frame” design. The large underbody & inter-body clearance allows free flow of soil & crop residue without getting clogged in the system.

The shear bolt protection system works as a safety device protecting the main parts of plough in case of some major obstacle in the soil to the forward working of the plough.

There are adjustments given on the plough to set the angle of the cutting points to the ground level, Center of Gravity of the pull of plough in reference to tractor & mold board curve to throw back the soil.

•Cylinder body and piston are made from solid chrome steel and heat-treated.

•Hard-chrome plated piston with replaceable, heat treated saddle.

•Stop ring can bear full capacity (pressure) and is fitted with dirt wiper.

•Forged, replaceable links.

•With carrying handle and piston protection cover.

•Oil port thread 3/8 NPT.

Service

1, Sample service: samples will be provided according to customer’s instruction.

2, Customized services: a variety of cylinders can be customized according to customer demand.

3, Warranty service: In case of quality problems under 1 year warranty period, free replacement will be made for customer.