using and maintaining

1. The viscosity of working oil used in the hydraulic cylinder is29~74mm/sIt is recommended touseIsoVG46 wear-resistant.

hydraulic oil.The normal working oil temperature range is between-20?~+80?.In the case of lower ambient temperature ancused temperature low viscosity oil may be usedPlease specify separately special requirementsif any.

2.The system filtration accuracy required by the hydraulic cylin der is at least 100 um.Care must be taken to control oil pollution and to keep oil clean.Check regularly the oil feature and use fine filter or replace with new working oil if necessary.

3.When installation make sure the piston rod head connecto has the same direction as that of the cylinder headeyeringo middle trunnion). Ensure the piston rod can move smoothly in its reciprocal stroke to avoid rigid interference and guard against unnecessary damage

4. After the hydraulic cylinder is installed on the main machine check whether there is oil leakage in the piping part and guiding sleeve in operation test.Lubricate the eye ring and middle trun nion bearing.

5. In the case of oil leakage, make use of hydraulic force to move the piston to either end of the cylinder when the hydraulic cylinder needs disassembly. Avoid unnecessary knocking and falling-down during disassembly.

6.Before disassembly,loosen the relief valve and decrease the pressure to the hydraulic circuit tozero.Then cut off power supply to stop the hydraulic equipment. Plug the ports with the plastic plugs when the port pipes are disconnected.

7. The hydraulic cylinder cannot be used as electrode for ground ing to avoid electrically damaging the piston rod.

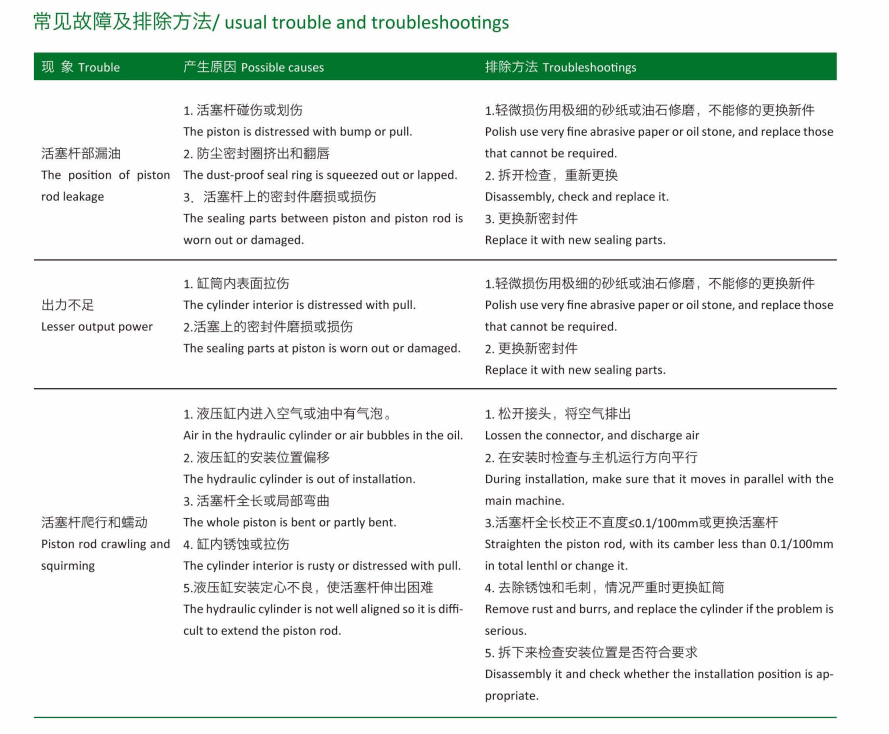

8. For usual trouble and troubleshootingsrefer to the following table in next page.

Post time: Jun-24-2022