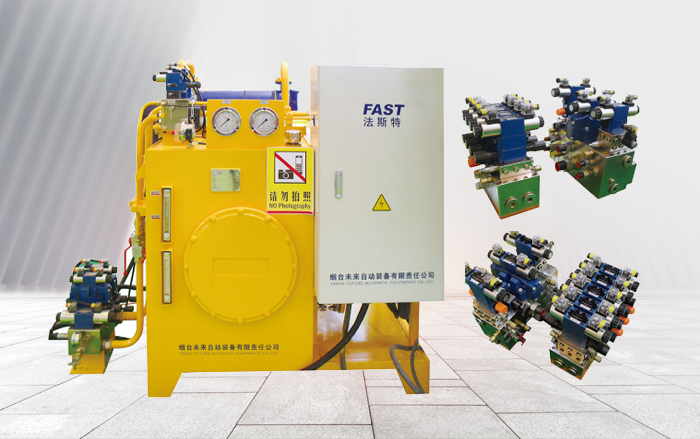

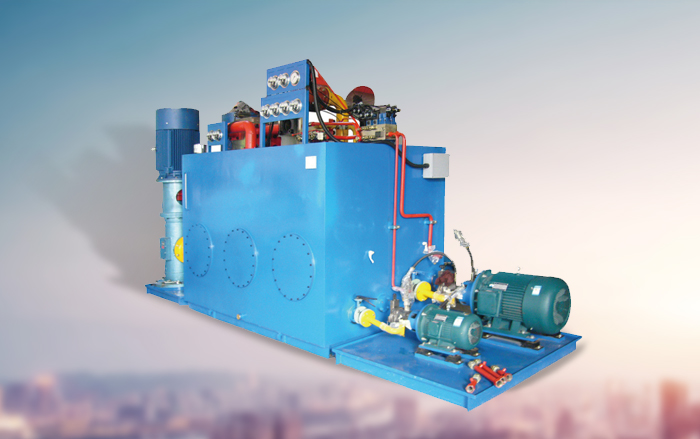

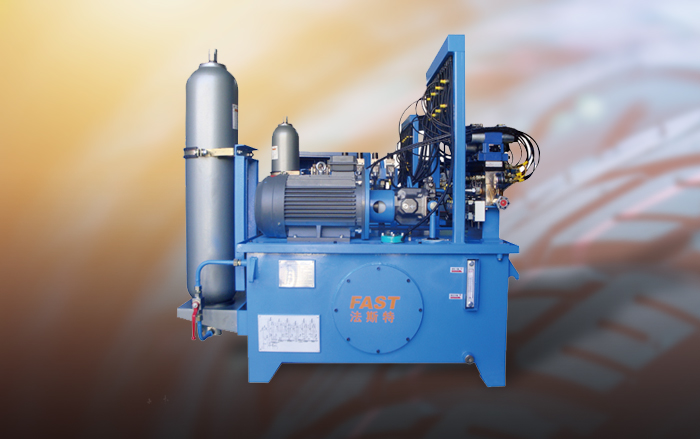

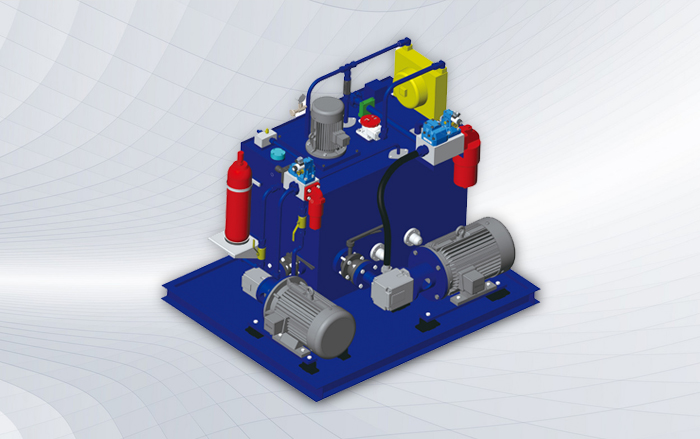

Hydraulic solutions for rubber machinery industry

Products are widely used in municipal sanitation, living garbage processing, special vehicles, rubber, metallurgy, military industry, Marine engineering, agricultural machinery, textile, electricity, chemical industry, engineering machinery, forging machinery, casting machinery, machine tools and other industries, with major enterprises, colleges and universities has established good relations of cooperation, with excellent quality and thoughtful service has won widespread praise.

In 1980, it became one of the core suppliers of Baosteel Joint Research and Development Center. In 1992, we started to cooperate with Mitsubishi Heavy Industries of Japan in the production of oil cylinders. From the production of spare parts to the assembly of oil cylinders, we inherited Japanese technologies and processes. After entering the 21st century, it has absorbed the technology and process from Germany and The United States. It has unique technology and skills from product design to production process and design and selection of key parts, which ensures the quality, reliability and innovative development of products.